Reimagining Hydrogen Infrastructure

November 2025 / World Pipelines

by Robert H. Shelton

In a previous World Pipelines article, Robert H. Shelton, CEO of H2C Safety Pipe, Inc., explored how the historical development of natural gas pipelines and underground petroleum storage tanks offers a roadmap for building a safe and scalable hydrogen infrastructure. This follow-up article focuses on what that future must look like in practice. As the hydrogen economy accelerates, traditional approaches to pipeline safety, monitoring, and financing are proving increasingly inadequate for the demands of this unique, low-carbon, and highly versatile energy carrier.

This article presents a technical and financial blueprint for a new class of hydrogen pipelines conceived from the ground up. It introduces dual-containment pipe architectures, continuous annular monitoring systems, and financing models designed to mitigate risks in early-stage deployments. These innovations are not just theoretical — they are being actively advanced through real-world projects by H2C Safety Pipe (H2CSP) and its partners in North America and Europe.

Before diving into the details of this technical and financial approach, it’s important to ask a more fundamental question: why must hydrogen pipelines be reimagined from the ground up; and why now?

The Logistics Challenge of Hydrogen Delivery

The reason is simple: reliable and cost-effective delivery and storage remain the Achilles’ heel of transitioning to hydrogen. Everyone familiar with energy systems understands that hydrogen’s ability to store energy over days, weeks, or entire seasons; to fuel buses, heavy-duty vehicles, and massive data centers; and to provide high-temperature heat for industrial processes such as cement, steel, and chemical manufacturing, makes it one of the most versatile tools for both resiliency and deep decarbonization. But versatility alone doesn’t guarantee viability.

Without affordable, highly reliable delivery systems, hydrogen will remain geographically stranded. It will continue to offer enormous potential in regions where low-cost natural gas, wind, solar, or hydro power make it inexpensive to produce. But unless and until it can be transported safely, efficiently, and at scale, hydrogen will remain economically uncompetitive in the very places where clean energy is most urgently needed.

Pipelines are the only scalable solution to this distribution challenge. Yet in practice, many hydrogen projects still default to truck-based delivery. While this may seem prudent for the flexibility it offers in early-stage deployments, this makes small volumes of hydrogen even less economically viable; and becomes both logistically and economically unsustainable at scale.

Why Trucking Hydrogen Doesn’t Scale

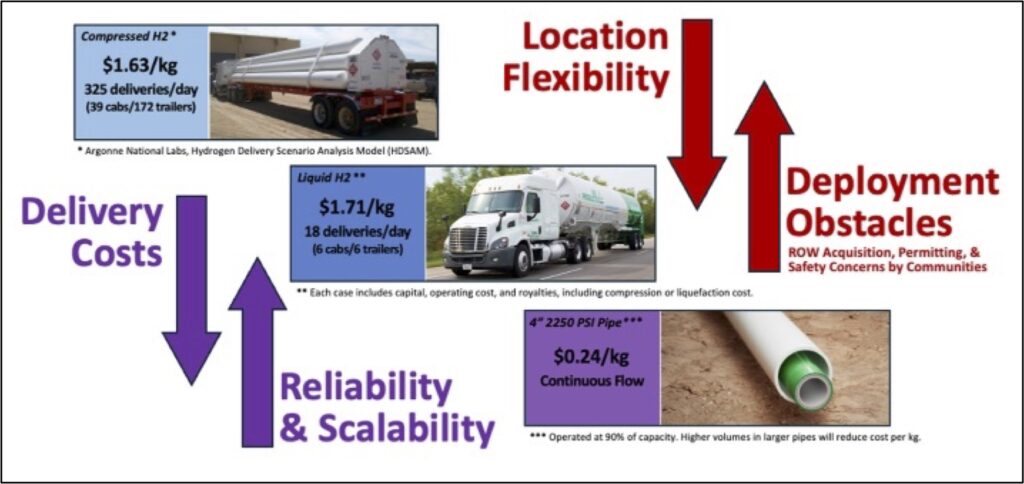

At its core, this is a logistics problem. Consider the case of delivering 65 tpd of hydrogen to an industrial off-taker located 25 miles away. This volume is sufficient to achieve production-scale economies when produced using low-cost electricity or natural gas reforming, but the economics break down without a reliable, cost-effective transport solution.

Using compressed hydrogen (GH2) tube trailers require 325 deliveries per day, involving a fleet of 39 cabs and more than 170 trailers, along with drivers, depot infrastructure, and extended loading times. This contributes to a delivery cost of US$1.63/kg. Liquid hydrogen (LH2) reduces the number of trips to just 18 per day, but raises the cost to US$1.71/kg, due to energy-intensive liquefaction and cryogenic storage requirements.

Now compare both to a dedicated 4 in. (100 mm) hydrogen pipeline rated at 2250 psi (155 bar). The same 65 tpd can be supplied continuously at an estimated cost of just US$0.24/kg – with no trucks, no liquefaction, no cryogenic handling, and no need to put drivers on the road 24 hours a day. This represents an 85% reduction in delivery cost compared to compressed hydrogen and even greater savings over liquid hydrogen, while eliminating hundreds of truck movements each week. For longer distances or higher capacities, the advantages become even more pronounced.

Figure 1 illustrates this contrast in both cost and operational burden, reinforcing why pipelines — despite permitting and right-of-way challenges — are not just a better option. They are the only viable option at scale.

Why Traditional Pipelines Also Fall Short

But building pipelines for hydrogen, especially in ways that address leakage risk, right-of-way limitations, and capital market expectations, demands a clean-sheet approach. Simply retrofitting old petroleum pipelines or relying on design practices developed for methane is no longer sufficient. Hydrogen embrittles metals, escapes through microcracks, cannot be odorized, and is invisible to conventional aerial plume detection — making traditional leak detection methods ineffective, as PHMSA concluded in its 2025 Final Rule on gas pipeline leak detection and repair.

Moreover, hydrogen has one of the widest flammability ranges of any fuel and, when mixed with air in enclosed or semi-enclosed spaces, poses a significant risk of explosion that concerns communities. Also, recent studies by the Environmental Defense Fund, MIT, and others have raised concerns that hydrogen leakage into the atmosphere may contribute to global warming more significantly than CO2 on a per-molecule basis. Together, these safety and environmental concerns make even low-level hydrogen leaks unacceptable, particularly in densely populated or industrial areas, and anywhere that ignition sources may be present.

California’s Hydrogen Pipeline Safety Act

Legislators are beginning to acknowledge this reality. California’s Hydrogen Pipeline Safety Act (SB 804) directly targets the unique risks associated with dedicated hydrogen pipelines. Co-authored by State Senator Bob Archuleta, Chair of the Senate Select Committee on Hydrogen Energy, and Assembly Member Cottie Petrie-Norris, Chair of the Assembly Utilities and Energy Committee, the bill was supported by industry, environmental groups, and organized labour, and has faced no formal opposition. It was unanimously approved by members of both political parties in all five Senate and Assembly committees in which it has been heard, as well as on the Senate Floor. The bill is scheduled for a vote in the full Assembly when the Legislature reconvenes in January 2026.

The bill lays out five core standards for dedicated hydrogen pipelines:

- Design and construct pipelines to minimize hydrogen leakage to the lowest technically feasible level

- Employ continuous measurement and monitoring systems to detect deviations from normal operating conditions

- Use materials that are hydrogen-compatible and resistant to degradation such as corrosion and embrittlement

- Submit annual reports demonstrating compliance with recordkeeping and safety standards

- Ensure consistent enforcement across all jurisdictions in the state, with periodic updates reflecting evolving technologies and best practices

Together, these provisions establish a new regulatory baseline for hydrogen pipeline development — not only in California, but in any jurisdiction serious about catalyzing safe, scalable hydrogen deployment. SB 804 is more than a safety statute. It reflects a shift in pipeline design philosophy to one that starts with hydrogen’s unique properties and builds from the ground up to accommodate them.

A Next-Generation Technical Architecture

Even as this direction becomes clearer, there is still no global standard for what constitutes a ‘bankable’ hydrogen pipeline. As a result, any pipeline planned today must meet two critical tests: compliance with evolving safety regulations tailored to hydrogen’s unique characteristics, and alignment with the expectations of lenders, insurers, and commercial off-takers. In short, hydrogen pipelines must be designed not only to operate safely, but to attract capital more effectively.

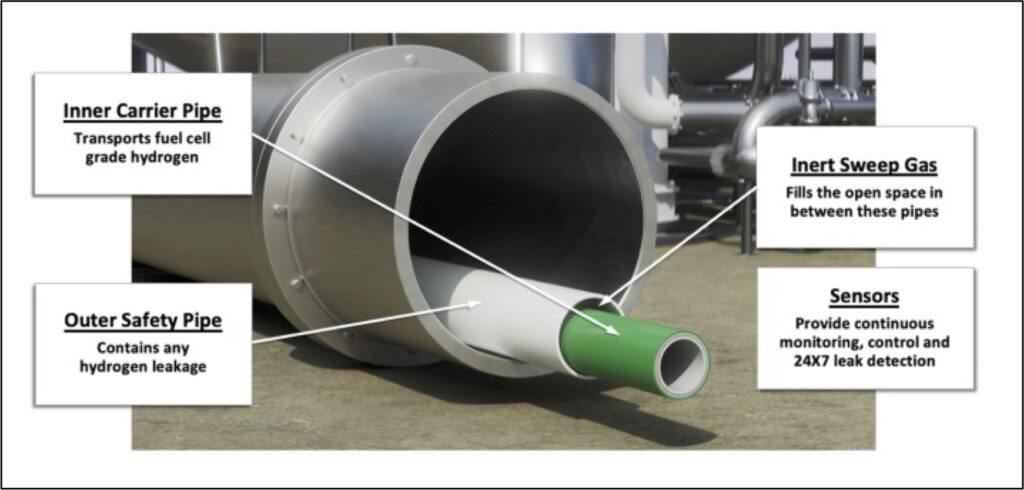

This is precisely the gap that next-generation architectures such as H2CSP’s Safety Pipe™ system are designed to fill. The system (see Figure 2) uses a dual-containment pipe-in-pipe configuration, with a sweep gas circulating through the annular space to enable 24/7/365 leak detection. Hydrogen sensors continuously monitor this sweep gas stream, enabling real-time detection, localisation, and reporting of any deviations — while also building a dataset that can be analyzed using pattern recognition and AI tools to predict future points of concern.

This continuous monitoring approach replaces not only the snapshot-in-time model of legacy in-line inspection, but also the reactive, ‘report it when you smell it’ or ‘respond when the pressure drops’ paradigms that have long characterized leak detection in conventional gas networks. In place of periodic pigging, patrols, and human-dependent alerts, it provides digital oversight with continuous visibility, early warning of emerging threats, and actionable diagnostics.

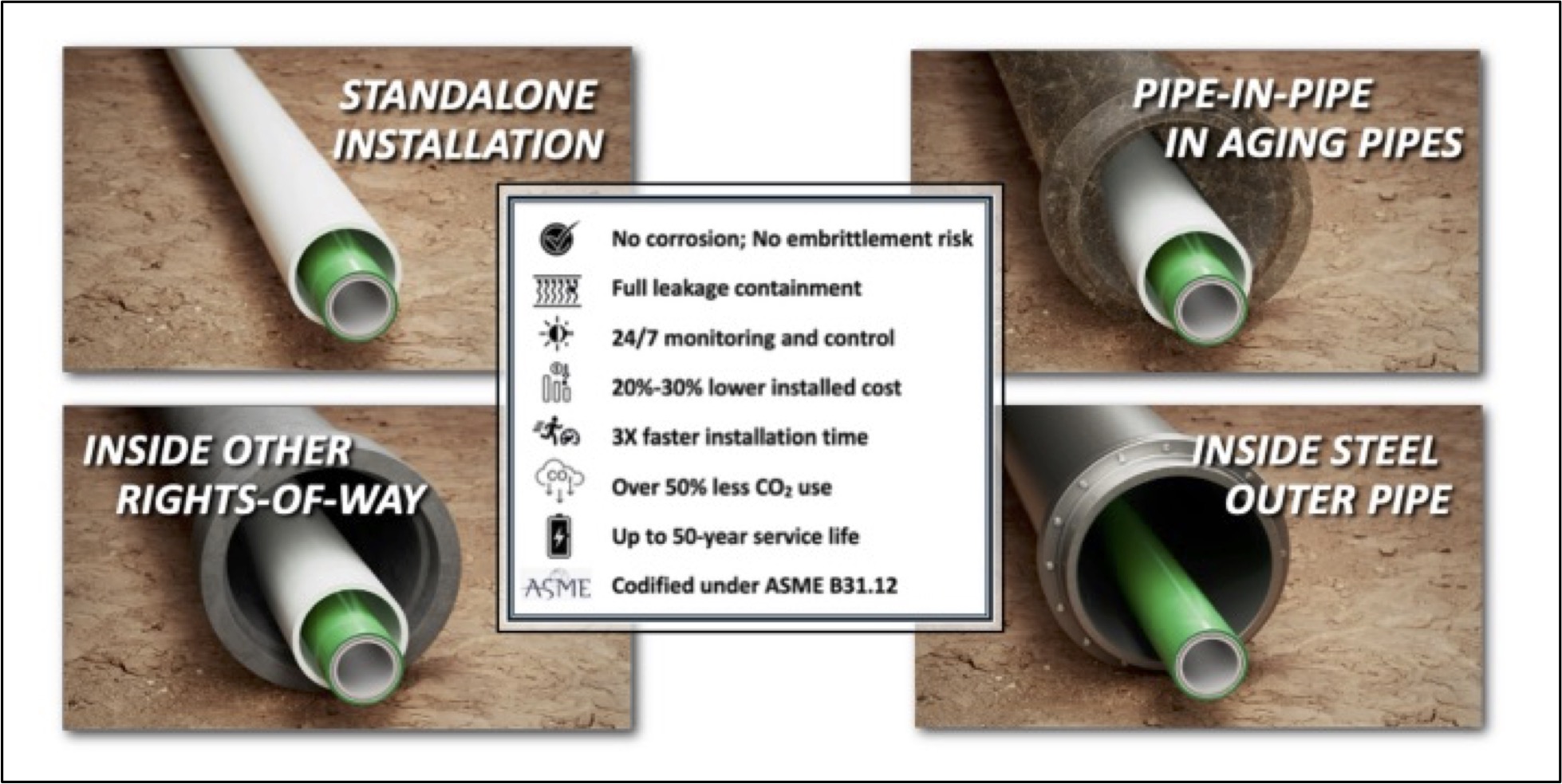

Equally important, this architecture enables a broader range of materials and deployment strategies. It supports the use of hydrogen-compatible non-metallic pipe materials such as HDPE and fiberglass reinforced polymer (FRP), which allow for faster installation, fewer welds and connections, and lower installed cost, while minimising the risks of embrittlement and corrosion. Using modern line-pull technology, these lightweight materials can be installed inside existing pipelines, along public rights-of-way, within shared utility corridors, or in new trenches, and completed in weeks rather than months.

This deployment flexibility (see Figure 3) translates into real-world benefits, including 20-30% lower installed cost, three-times faster installation timelines, and reduced community concerns about hydrogen safety.

Real-World Validation

In 2024, H2CSP completed a prototype deployment of the Safety Pipe™ system at a client site in Houston, Texas. The project validated the system’s core functions of continuous leak detection, sweep gas circulation, real-time hydrogen sensing, and automated system response. It also confirmed the viability of the dual-containment design under real-world installation conditions.

Building on this foundation, several commercial-scale projects are now being advanced by H2CSP in California, Spain, and Canada. These initiatives aim to support midstream hydrogen delivery from producers to off-takers using both retrofitted and newly constructed pipeline segments. In each case, the goal is to deploy systems that are safer, faster to place in service, easier to monitor, and aligned with the financial and regulatory expectations of today’s hydrogen markets.

A Financing Model for Early Deployment

While large-scale ‘build-it-and-they-will-come’ trunk line projects may ultimately play an important role in the hydrogen economy, many are being pursued ahead of market demand and therefore require substantial public support to proceed. In the current political and economic climate, this reliance on government funding can introduce delays and increase uncertainty. By contrast, near-term projects can be structured around private infrastructure ownership models focused on improving reliability and lowering delivered hydrogen costs.

Ideally, these initiatives connect a regional hydrogen producer directly with an industrial off-taker. H2CSP and a local hydrogen-focused engineering partner design and implement the pipeline on behalf of a special purpose project vehicle, capitalised through private equity and project debt, and anchored by a long-term capacity commitment from the producer and/or off-taker. Because this commitment reflects an existing or planned agreement to buy and sell hydrogen, the pipeline provides an off-balance sheet mechanism to enhance contract certainty and reduce overall cost.

Over time, hydrogen pipelines are likely to be owned and operated by public or quasi-public utilities to ensure equitable access, capital efficiency, and alignment with long-term decarbonisation goals. But in today’s market, where hydrogen production and off-take remain limited, right-of-way acquisition and permitting are complex, and ratepayer-funded infrastructure is subject to increasing scrutiny, private-sector leadership or public-private partnerships may offer the most practical path forward.

Financial models that allow infrastructure to be developed, de-risked, and validated before being transferred to public ownership are critical to minimising ratepayer risk and accelerating deployment. One proven approach is the Build-Own-Operate-Transfer (BOOT) model, in which infrastructure is privately financed, built, and operated for an initial period, then transferred to a utility or other long-term owner/operator once performance and commercial viability are demonstrated. This structure enables public agencies to benefit from private sector speed, technical expertise, and risk tolerance, while ensuring transparency and long-term strategic alignment.

While BOOT is one established pathway, other proven infrastructure financing models, including those historically used in oil and gas pipeline development, may also be useful. When supported by dedicated infrastructure funds and project debt, these structures can help scale deployment and manage early-stage risk.

From Bottleneck to Strategic Enabler

As these frameworks are implemented, the Safety Pipe system offers a practical solution to one of hydrogen’s most persistent barriers: delivering clean hydrogen safely, affordably, and at scale. By addressing the sector’s core technical and financial requirements, Safety Pipe transforms the midstream from a legacy bottleneck into a strategic enabler of the hydrogen economy — helping to ensure that the promise of hydrogen is not just imagined, but delivered.